Task Description

At its core, this competition is based on real dual-arm humanoid robots, with several tasks thoughtfully prepared that are highly representative of typical industrial applications workflow. In addition, a simulation environment that closely resembles the task workflows of the real robot is also provided, along with open access to high-quality task datasets, evaluation scripts, complete execution pipelines, online evaluation servers and ready-to-run baseline code. The simulation track is especially designed for competitors to familiarise themselves with the Kuavo robot dataset formats, algorithm development and algorithm testing with our baseline code. It also simulates and selects teams with highly matured algorithms that are highly worthy of real-robot competition in a fair manner.

Simulation Task Description

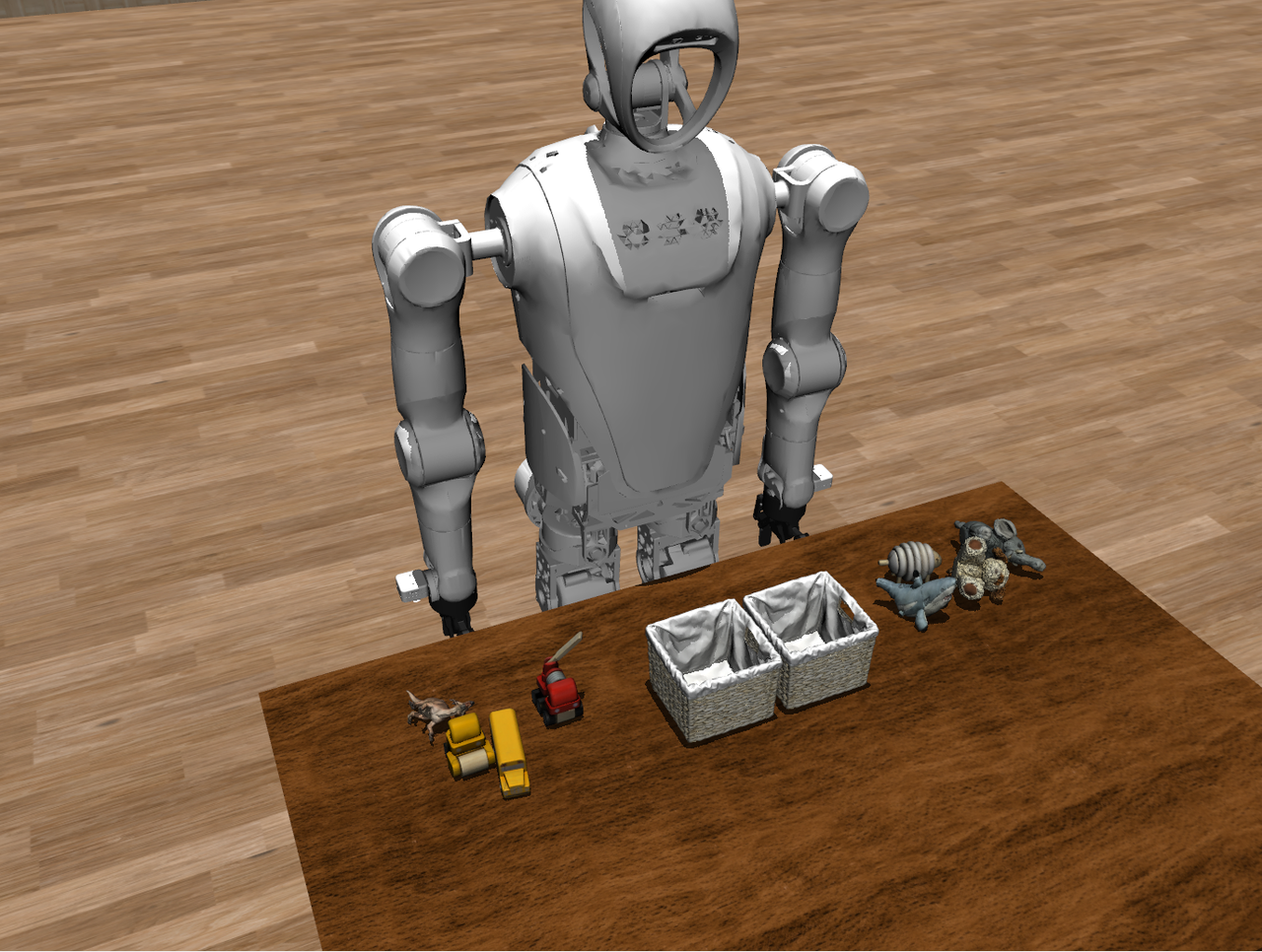

Task 1: Toy Sorting

In this task, there will be assorted toys randomly laid out on a desk surface. The robot needs to grasp the toys, and place all the animal toys into the right basket, while all the car toys go into the left basket.

Within this task, the robot will start from a reasonable randomised location away from the desk; the height of the desk as well as the assortment of toys on the desk are also randomised.

- Scoring standards:

40 pts for every correct placement of each of the toys

20 pts for completing it within a specified timeframe. 1-pt penalty will be applied for every second elapsed outside of this timeframe

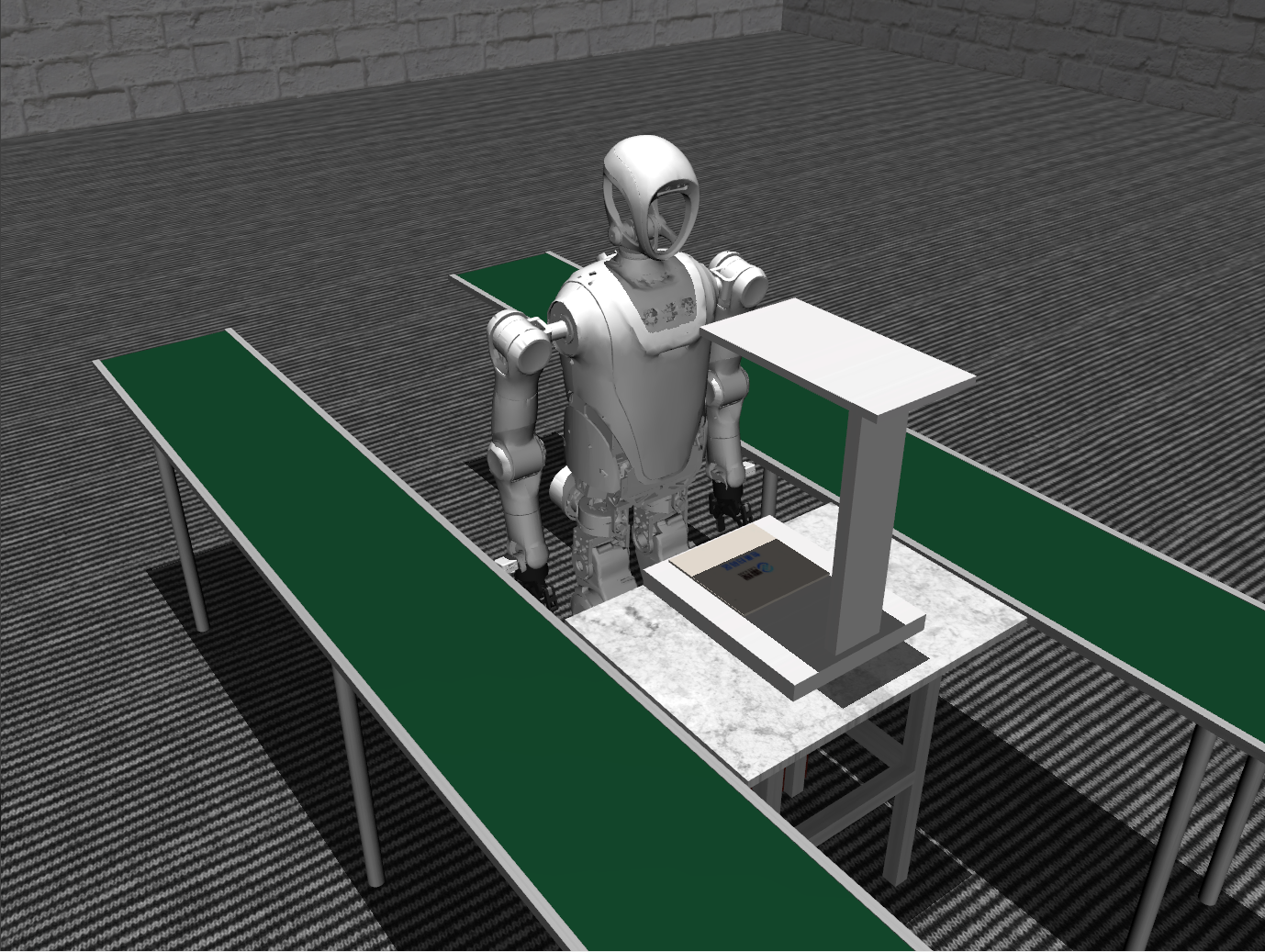

Task 2: Parcel Weighing

In this task, the robot is required to pick up a soft-pouch express parcel from a moving conveyor belt, place it on an electronic scale for weighing, and then transfer it to another conveyor belt.

Within this task, the positioning of the parcel and the scale will be randomised within a reasonable range.

Each task is out of 100 base points as the base task score.

- Scoring standards:

40 pts for the correct placement of the object onto its desginated area (the electronic scale)

40 pts for the correct placement of the object after weighing

20 pts for completing it within a specified timeframe. 1-pt penalty will be applied for every second elapsed outside of this timeframe

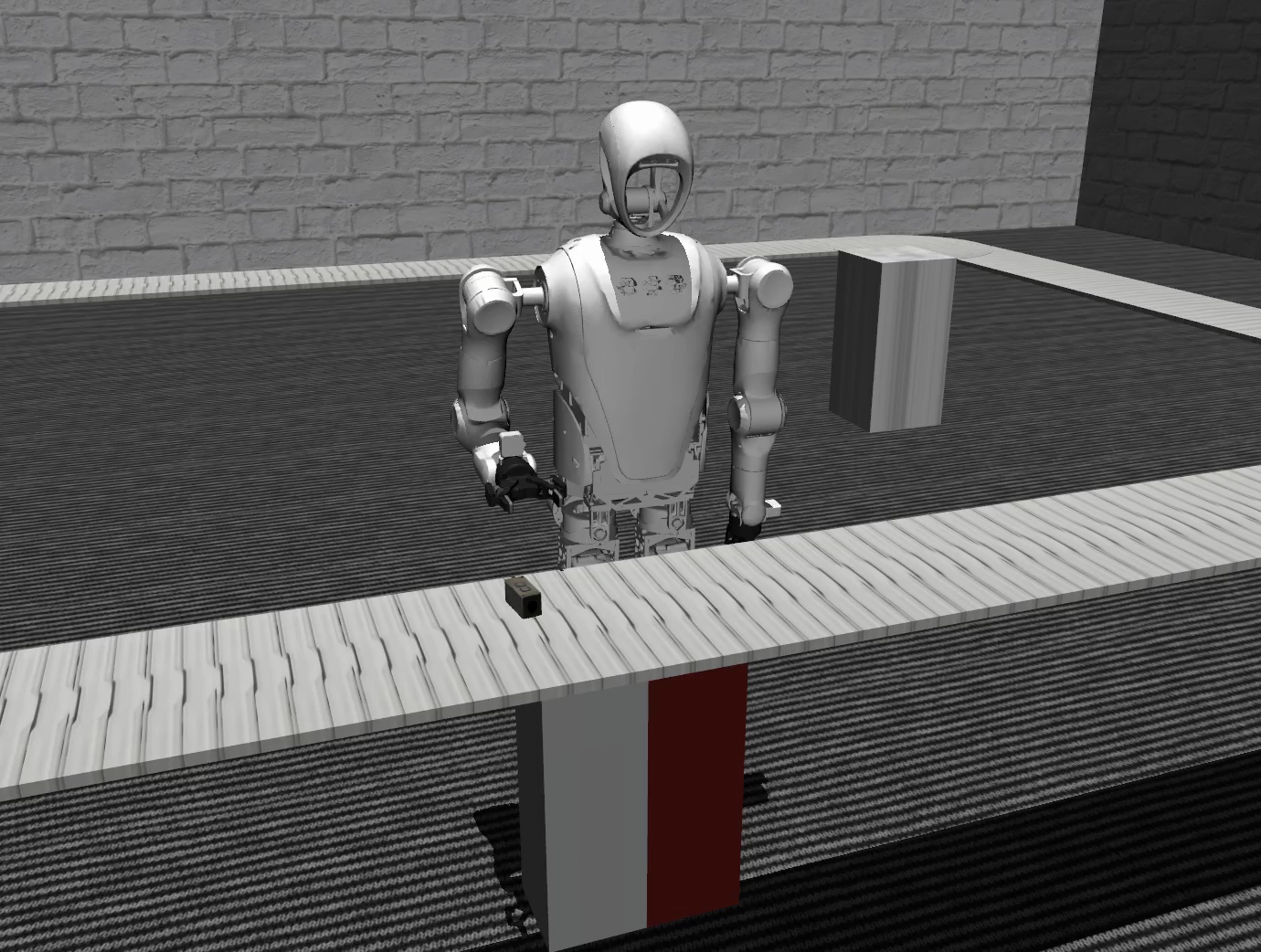

Task 3: Conveyor Belt Parts Sorting

In this task, the robot needs to pick up a component chosen from different categories representative in the industrial setting, lying in a randomised orientation on a moving conveyor belt, and then place the component into the correct sorting bin. Four such components are given in this task, and the task is considered as successful after correct placements of all four such components.

Within this task, the height of the conveyor, the positioning and orientation of the component, as well as when the component will be dropped off onto the conveyor belt, will be randomised within a reasonable range.

- Scoring standards:

20 pts for each successful sequence of grasp and final placement of each of the components

10 pts for successful completion of all four components in a row

10 pts for completing it within a specified timeframe. 1-pt penalty will be applied for every second elapsed outside of this timeframe

Real-machine Task Description

Task 1: Rubbish Sorting

In this task, there will be assorted refuse randomly laid out on a desk surface. The robot needs to grasp the rubbish pieces one-by-one, and place all the recyclable items into the blue bin, while all the other rubbish go into the grey bin.

Task 2: Parcel Weighing

In this task, the robot is required to pick up a soft-pouch parcel from a moving conveyor belt, place it on an electronic scale for weighing, and then transfer it to another conveyor belt.

Each task is out of 100 base points as the base task score.

Task 3: Conveyor Belt Parts Sorting

In this task, the robot needs to pick up a component chosen from different categories representative in the industrial setting, lying in a randomised orientation on a moving conveyor belt, and then place the component into the correct sorting bin. Four such components are given in this task, and the task is considered as successful after correct placements of all four such components.